Testing, Adjusting Services Across Australia

in Australia

Measuring

Precision Counts

Testing

Accuracy Guaranteed

Certification

Standards Verified

Nationwide Service

Anywhere, Anytime

AIRXPRESS TESTING

Services

SERVICES- HVAC All seasons service network is second-to-none when it comes to HVAC equipment installation, repair and maintenance in Australia.

- Hydraulic At AirXpress Testing, we always ensure that your hydraulic systems are installed and integrated to operate on a system level per the design intent and sequence of operations.

- Fire There are only few things more dangerous than playing with fire, which is why we take the business of protecting your business so seriously.

- Electrical AirXpress Testing has been successfully working in the field of electrical engineering and control equipment for over a decade now, offering solutions that adhere strictly to industry codes and standards.

- Energy AirXpress Testing can measure the energy losses by identifying the air leakage and air drafts of a building leading to reduce the energy consumption and improve the energy efficiency of the property.

- Safety AirXpress Testing believes "Safety is first" that is why we want to support your business meeting this. We are your source for the floor safety industry.

About Company

Optimizing HVAC Systems for Efficiency and Safety

We specialise in HVAC system optimization, delivering precise air balancing, pressure testing, and performance verification services that improve airflow, reduce energy costs, and extend equipment lifespan. Our HVAC commissioning experts ensure every component meets industry standards, helping your system operate at peak efficiency across Australia.

Our specialised services include:

- Air Balancing

- Water Balancing

- Air Quality Testing

- Car Park Exhaust Inspections

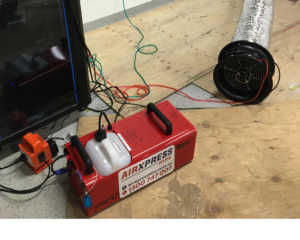

- Duct Leakage Testing

- Laboratory/Clean Room Pressure Testing

- Plant Performance Testing

- Stairwell pressurisation

Comprehensive HVAC Testing & Commissioning for Industrial Facilities

AirXpress provides industrial HVAC testing solutions to meet regulatory and operational demands across sectors including healthcare, retail, education, and manufacturing. Whether it’s a new construction project or a system upgrade, our certified HVAC Balancing Specialists and engineers deliver air performance evaluations and HVAC commissioning services with accuracy and speed.

184

Domestic

356

Commercial

250

Industrial

49

Events

AIRXPRESS TESTING

Projects

PROJECTS

Clean Room Pressure Testing – Riverside Dental Spa

Industries: Facility Management Location: West Gosford, NSW Client: Riverside Dental

Aircon Duct Leakage Test – Wagga Wagga

Industries: Facility Management Location: Wagga Wagga, NSW Client: American Satellite

Smoke Leakage Testing – Wagga Wagga

Industries: Facility Management Location: Wagga Wagga, NSW Client: American Satellite

Technical Support

Certified HVAC Balancing & 5 Years Warranty on System Performance

At AirXpress Testing, we pride ourselves on offering top-notch HVAC testing and air balancing service comes with a 5-year workmanship guarantee, ensuring long-term energy efficiency and optimal airflow across your buildings.

- 01 Request to call of master

- 02 Date and time assignment

- 03 Repair and maintenance at your home

Book a free visit

of our professional engineer

- Free Shipping Free shipping on all orders

- 5 Years Guarantee 5-year warranty for durability

- Discount System Exclusive discounts for loyal customers.

- Online Payments Secure and convenient payment options.

- Certified Products Certified products meeting top industry standards.

- Fast Support 24/7 prompt customer support for any queries.

Testimonials

What our clients say

Fast response, quick delivery, price was good considering it included hire, delivery, installation and pickup. Saved me having 6 people all wanting.

The service & pricing was unbeatable from this company. Fast delivery, clear instructions on how to use. Would highly recommend them for.

They handled themselves with utmost professionalism. Were very quick and fast for our breakdown emergency. We wanted to hire an evaporative cooler.

Conrad from AirXpress was able to install a temporary air-conditioner the in our small studio same day as our enquiry. Pricing was.

Commited to bringing quality in his work and service. His Polite and happy to always be able to help. Thank you Conrad..

Subdivision

AIRXPRESS GROUP

We work with

Our Partners

We like to thanks

Accreditations