Test and tagging, a crucial service offered by AirXpress Testing, involves the meticulous process of visually inspecting and electrically testing in-service electrical equipment to ensure personal safety. This essential service goes by various names, including tagging, test tag, electrical tagging, appliance testing, portable appliance test, or lead tagging. Regardless of the name, the objective remains the same: to verify the electrical safety of appliances for everyday use.

Why is this necessary?

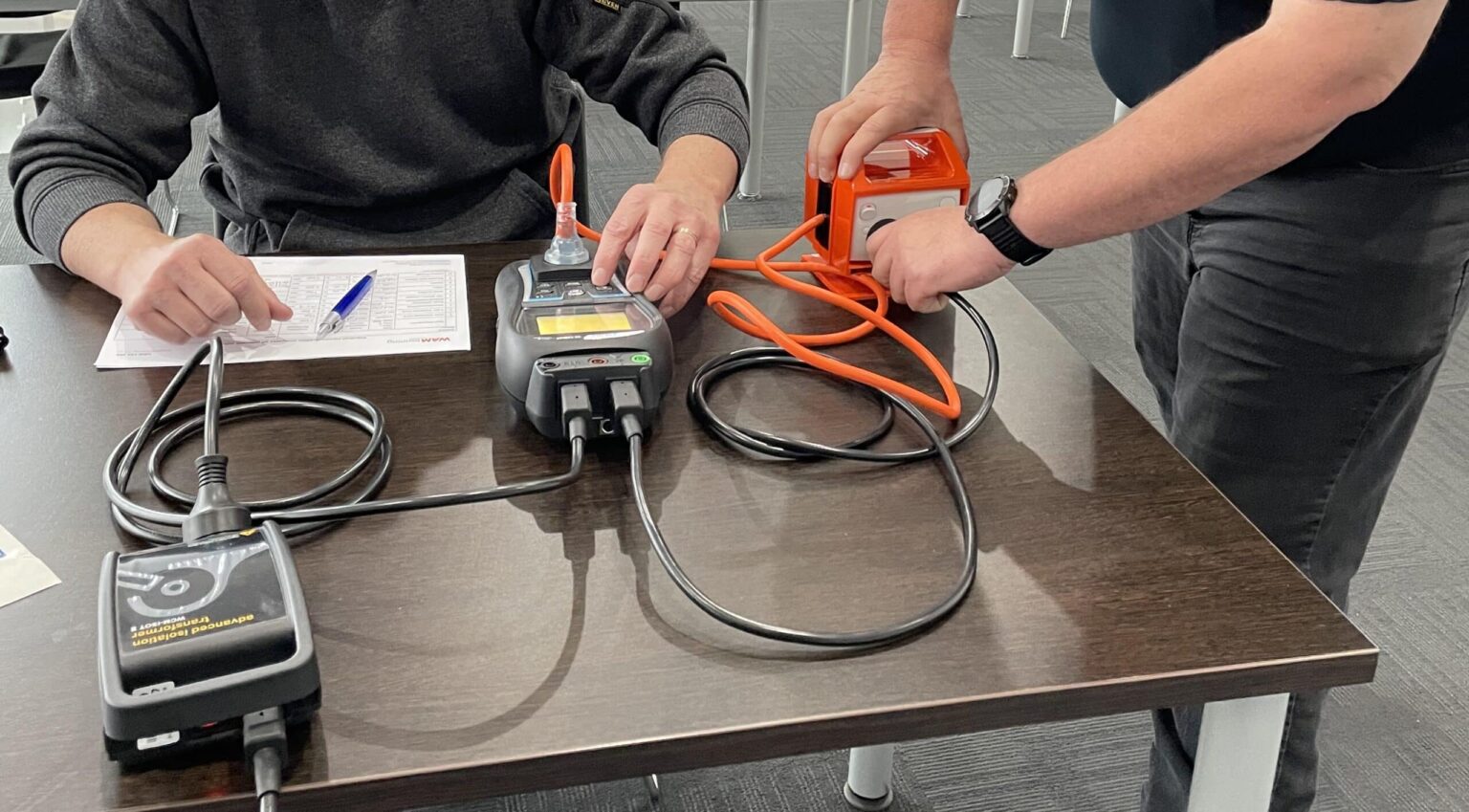

Ensuring the safety of electrical appliances through test and tagging is paramount for several reasons. The primary goal is to ascertain that each appliance is electrically safe for personal use, preventing potential hazards. The process involves a comprehensive visual inspection to detect defects such as damage or missing components, followed by a series of electrical tests measuring earth continuity, insulation resistance, and polarity.

In Australia, this procedure adheres to the AS/NZS 3760:2010 standard, which outlines the protocols for in-service inspection and testing of electrical equipment. Regular yearly inspections of electrical tools, appliances, power leads, extension leads, and other workplace and home electrical equipment are critical for maintaining safety. Each year, numerous workplace-related deaths and serious injuries caused by electrocution or destructive fires occur, many of which could be prevented with regular test and tag inspections.

Compliance with Occupational Health and Safety (OH&S) legislation necessitates that businesses, contractors, and sole traders operating in a working environment conduct regular test and tag procedures on their electrical equipment. This compliance ensures adherence to the AS/NZS 3760:2010 standard, promoting a safer working environment.